Toyota Camry 2002-2006: How to Replace Rear Wheel Bearings

Wheel bearings are designed to eliminate the resistance to movement between the wheel and suspension. They are precision machined for a tight fit between the hub and spindle. Faulty wheel bearings can create major driveability issues such as vehicle wander, shimmy, or vibration making replacement very important.

This article applies to the Toyota Camry (2002-2006).

Inside of the wheel hub are the wheel bearings. These bearings "float" on the spindle, allowing the hub to rotate very easily. Wheel bearings are packed with grease to keep the bearings themselves and the races on the hub/spindle free from damage. Wheel bearings fail for a number of reasons, including age, impact of objects on the road such as potholes, and breaks in seals which let grease escape. When driving at slow speeds, a faulty wheel bearing will usually create a whirring or grumbling noise that gets louder as speed increases. Unlike some other vehicles, hubs can be purchased as a complete assembly with the bearings included for the Camry making installation much easier.

Materials Needed

- Impact wrench

- Breaker bar

- Socket set (8mm-19mm)

- 1/2" ratchet

- 6" 1/2 extension

- Pick

- Hammer

- 14mm wrench

- Floor jack

- Jack stands (x2)

Both styles of rear brake will be covered (drum and disc).

Step 1 – Remove rear wheel(s)

If you do not have an electric or air powered impact wrench, loosen the lug nuts one full turn before raising them off the ground. You may have to remove a plastic wheel cover. Do this by pulling along the edge of the cover until it pops off the lug nuts.

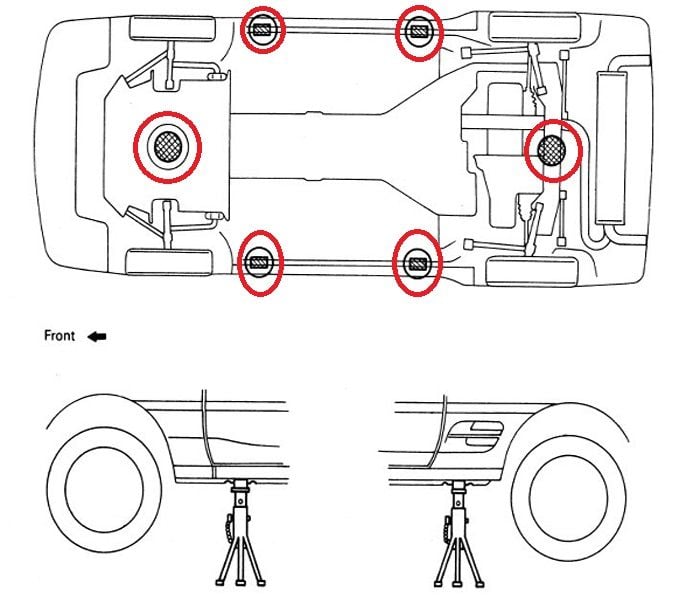

Raise the rear wheels off the ground with a floor jack and place jack stands beneath the frame rails on a level surface.

(Related article: How to Jack up Your Car. - CamryForums.com)

Step 2 – Remove brake drum / brake caliper

Owners with drum brakes will remove the brake drum. The drum will slide off the wheel studs with some force/wiggling. A hammer can be used to tap the face of the drum. This will break free any rust/dirt present.

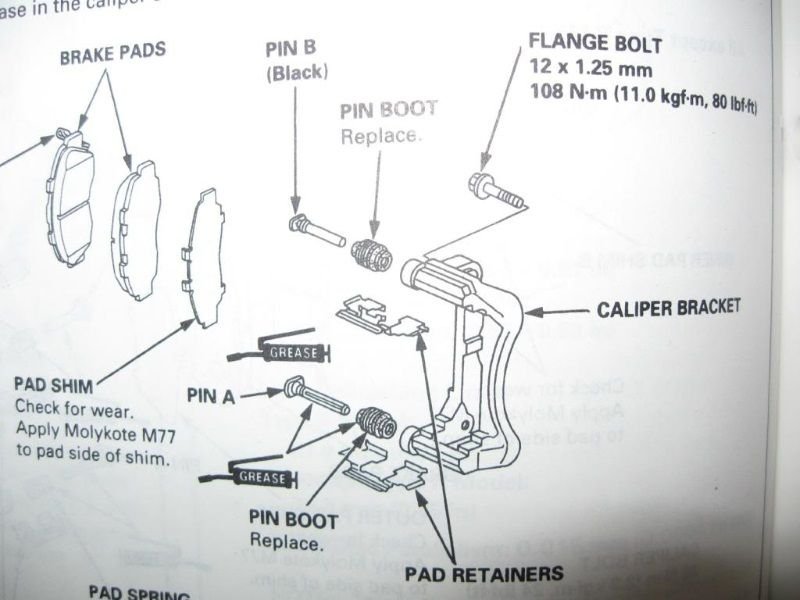

Disk brake owners will need to remove the caliper by removing the two caliper bracket flange bolts with a 14mm socket. If your rotor has a large lip on the outer edge, you'll need to compress the caliper piston. Place your hands on the back side of the caliper and squeeze it against the rotor. The caliper piston will not need to be compressed very far. Hang the caliper assembly from the suspension with a bungee cord or wire. Once the caliper is off, the rotor will slide off the wheel studs.

Step 3 – Remove hub from spindle

With the drum and rotor out of the way, you will see a hub face with two large holes. These are the access holes for a socket to reach into the hub. Four bolts hold the hub to the spindle. Spin the hub face to reach all four bolts. You may need a breaker bar for these bolts. Some models have an ABS sensor bolted to the backside of the hub that must be removed. Once the four bolts are removed, the hub will slide out of the spindle.

Figure 4. The two hub access holes.

Figure 5. A wheel speed sensor.

Step 4 – Install new hub assembly

Before placing the new assembly back onto the vehicle, check to see if your model has an O-ring around the front face of the spindle near the backing plate. If your hub assembly includes one of these make sure to replace it. A small pick can be used to reach it.

- Slide the hub assembly back into the spindle and place a bolt on the end of your socket. Start the bolt by hand then torque close to 40 ft./lbs. Give the hub a spin. There should be no grinding sounds.

- Reinstall the caliper and rotor/drum. Torque the caliper bracket bolts to 30 ft./lbs.

- Finish by re-installing the wheels and torque the lug nuts to 80 ft./lbs.

Featured Video: How to Change Rear Wheel Bearings

Related Discussion and Video

- 2009 Toyota Corolla Rear Hub DIY - YouTube.com

- Rear Hum Becoming Groan Noise - CamryForums.com