How to fix your defective sticky/melting XV40 Camry Dashboard before it gets worse.

#1

The sticky dash problem.

Under certain conditions, a combination of high humidity and high temperatures can cause the surface of some XV40 Camry/Aurion Dashboards to become sticky/melted, have a shiny appearance, emit a noxious chemical smell and ooze a yellowish adhesive compound that is sticky to the touch. Despite otherwise being pleased with their vehicles, owner's recognize that the deterioration of their Dashboard may be dangerous and reduce resale value.

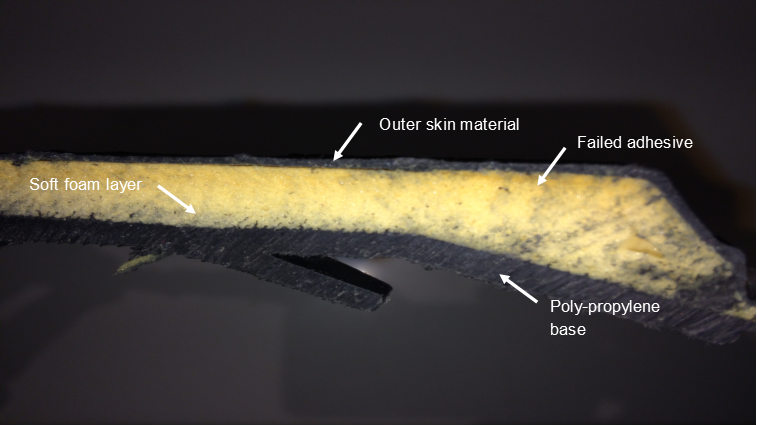

The defect explained.

Exposure to sunlight, heat and perhaps high humidity can cause the adhesive used to bond the layers to liquify and migrate downwards into the foam layer or upwards through the dashboard outer fabric. The outer fabric softens and expands when heated providing a "path of least resistance" for the adhesive to escape. This is most evident in the areas of the dashboard closest to the windscreen glass. Overtime, if not treated, the strong adhesive begins to soften and destroy the outer fabric of the dashboard. Just touching the soft sticky surface can leave indentations and gouges

“Sticky Dash Fix” - is a two-part process involving a special Surface Cleaner which prepares the dashboard surface before applying a colour-matched, microns-thin, flexible yet strong, protective membrane Surface Coating which together - adheres to and seals the dashboard surface, leaving the surface dry to touch, waterproof and matte. Developed and produced in Australia.

Instructions.

Additional things you will need that are not included in the kit:

Sticky Dash Fix - Surface Cleaner (Step 1)

Cleaning the dashboard correctly is a vital in preparing the surface of the dashboard before coating. Some dashboards will be very dirty and due to the black, tar-like stickiness of the surface may have attracted dust, insects and hair over time. Detailing products which often contain silicone and oils can reduce the adhesion of the coating.

Test the product first on an inconspicuous area. Spray onto the surface evenly.

! Be careful not to apply too much product at once or drips may run down the dashboard and potentially stain other parts of the dashboard or carpet.

Allow the product to penetrate for a few minutes. Using the lint free cloth provided, very lightly wipe the dashboard in one direction to remove any debris from the surface. Do not rub the surface as this could further affect the texture of the dashboard surface. Be sure to regularly turn over the cloth as it becomes soiled. This cleaning process can be repeated if necessary. Rinse the cloth thoroughly before re-using. Allow the dashboard to dry.

The dashboard cleaner is formulated specifically to prepare the sticky dash surface prior to applying the coating. Do not use the cleaner on the dashboard again for at least two weeks after applying the Surface Coating as it may soften or begin to remove the fresh coating. Please refer to the maintenance section for more information.

Sticky Dash Fix - Surface Coating (Step 2)

The dash should feel dry or much less sticky after cleaning, but the stickiness will eventually return over time or when exposed to high heat. Therefore the cleaning process should be carried out shortly before applying the coating. Do not apply the Surface Coating in direct sunlight or in hot weather as the product may dry on contact and may peel as more is applied. Do not apply if the temperature is below 10 degrees Celsius. To avoid dust particles sticking to the coating when it is wet, don't apply the coating on a windy day or alternatively apply in dust-free enclosed area. Shake the bottle thoroughly before use. Check for a correct colour match by dabbing a little of the product, using a sponge or cloth, to a small inconspicuous area and allow to dry before inspecting.

Use masking tape to cover the sunlight sensor which is usually located at the bottom middle of the windscreen, or to the left or right side of the dashboard. Also mask the trim at the base of both windscreen pillars and any other areas such as the heater vents. If you do manage to get some coating on the windscreen glass, wait until your dashboard is completely dry then peel the coating off the glass or if still wet, apply some methylated spirits to a cloth and wipe the coating away, followed by a clean with regular window cleaner. The coating will not adhere to poly-propylene (plastic parts such as hard interior trim) and will simply peel off if desired, but it is always best to mask these areas rather than clean them. When removing masking tape, be careful not to pull up the Surface Coating.

Pour a small amount of the coating onto a small plastic tray, lid or a disposable plastic plate. To begin with, only apply the Surface Coating to one side of the foam brush, this will allow you to get into the areas where the windscreen meets the dashboard, without getting the Surface Coating on the glass. Apply a light coat, in one direction, to the areas closest to the windscreen. The section closest to the windscreen is usually the worst affected because it traps heat and becomes the hottest when exposed to sun-light, this area will require multiple coats. Make sure you routinely wipe the foam applicator brush with a dry cloth, to remove any debris which may have been missed when cleaning this area. Be sure to flatten any air tiny air bubbles on the surface, before the coating begins to dry. Wash the foam applicator sponge with water or wrap in cling wrap, between coats to preserve it.

Allow 30 minutes for the product to dry before applying another coat or a hair-dryer on a low setting may be used to speed-up the drying process. You will know when an area has been sufficiently coated, because it will no longer feel sticky to touch when dry. Apply the coating to other affected areas of the dashboard. It is possible to only coat the affected sections of the dash and lightly blend in the surrounding area.

Chips, gouges and scratches to the dashboard surface can be improved and filled by using a suitable flexible filler to fill indentations and then the colour-matched Surface Coating applied over it to conceal the repair.

! This Surface Coating is not suitable and should never be used in an attempt to fill or conceal cracks in your dashboard.

Although the product is touch-dry in minutes, the coating will continue to cure and strengthen over time. The coating can be stored (not in vehicles) and re-applied if ever required.

Use water to clean up.

WARNING! - AIRBAG CAUTION

Most modern cars are equipped with a passenger-side airbag that deploys through precisely designed perforations in the dashboard. The parts affecting airbag release are designed with great attention to detail, with the recognition that in an accident it is essential that they deploy as designed. Thus the spacing and size of the perforations designed to facilitate the properly timed and located airbag release are subject to extremely precise specifications.

It is vitally important that this area is not covered or restricted in any way. Please refer to your vehicle's owner manual or contact your vehicle's manufacturer to ascertain where the passenger airbag perforations are located and DO NOT APPLY THE COATING OVER THE AIRBAG PERFORATIONS OR AIRBAG DEPLOYMENT AREA. Never apply the coating to the driver's airbag cover or to any other areas from which airbags deploy. If applied in error, wet coating may be removed by gently wiping the area with a soft cloth dipped in methylated spirits. Coating which has completely dried will, begin to soften in contact with the methylated spirits and begin to wipe away.

USEFUL TIP: If the passenger-facing section of the dashboard is affected and requires coating, masking tape can be used to exclude the area from which the passenger airbag deploys and removed while the coating is still wet. To minimize noticeable lines, wait until the coating is dry and using a finger or applicator dipped in methylated spirits, gently soften and smooth the edge of the coating line. After the coating has properly cured, the Sticky Dash Fix - Dashboard Cleaner can be used occasionally to treat the un-coated section.

Maintenance

No special maintenance is required. Clean as normal with soapy water. Avoid commercial cleaning products. ! Never apply detailing products or dressings to the coated dashboard.

Trouble-shooting

Bad adhesion - residue from previously applied silicone dressing, is the most common cause of poor adhesion to areas or patches of the dashboard surface. If the Surface Coating is applied to a contaminated area, the coatings may disperse (spread out), appear patchy or peel off easily. Clean the affected area gently, using a finger or applicator dipped in methylated spirits (do not rub). On a positive note - if the coating does peel, it will often take most of the contaminant with it. Thoroughly clean or change the applicator, before re-applying the coating to the area, using a light dabbing or patting technique. Be sure to flatten any air bubbles before the coating begins to dry.

Shrinkage - if the coating is applied in direct sunlight or when the dashboard is hot, the coating may dry too quickly and shrink, resulting in a "crocodile skin-like" appearance. Use methylated spirits on your finger or applicator to soften and smooth the coating, allow the coating to dry.

Peeling - if the coating is not left to dry properly in-between coats, the membrane may peel when you apply the next wet coat. (Also see - Bad adhesion)

Broken or torn membrane - a break or hole in the Surface coating can be rectified by dipping a finger or applicator brush in methylated spirits and then lightly smoothing and flattening the edges of the broken coating and then re-applying the coating to the missing area using a light dabbing or patting technique. Be sure to flatten any small air bubbles. Once dry, the section can be lightly blended with the surrounding area.

Debris stuck in coating - methylated spirits can be used to soften the Surface Coating to remove debris or hairs which have attached to the coating during application and dried on the surface.

Section remains tacky - each dashboard has been exposed to different conditions over time and will vary in condition. Certain areas of the dashboard are exposed to more light and heat and will require more coats to seal the surface. If you have missed a spot during application or more coats are required to an area, simply repeat the application procedure without using the dashboard cleaner. The dashboard should feel dry even when parked in the hot sun. Never press down hard or poke the surface of the dashboard when it is hot, as the underlying surface (not the coating) may be soft.

Streaking - apply the Surface Coating evenly using a consistent amount of coating on the applicator. In addition to the foam applicator brush provided, a small foam sponge such as a cut-up kitchen sponge can also be used to better blend the area.

Additional things you will need that are not included in the kit:

- Masking tape

- Methylated spirits

- Small plastic tray or disposable plate/bowl

- Optional(Recommended) - Small Mohair Paint Roller

Sticky Dash Fix - Surface Cleaner (Step 1)

Cleaning the dashboard correctly is a vital in preparing the surface of the dashboard before coating. Some dashboards will be very dirty and due to the black, tar-like stickiness of the surface may have attracted dust, insects and hair over time. Detailing products which often contain silicone and oils can reduce the adhesion of the coating.

Test the product first on an inconspicuous area. Spray onto the surface evenly.

! Be careful not to apply too much product at once or drips may run down the dashboard and potentially stain other parts of the dashboard or carpet.

Allow the product to penetrate for a few minutes. Using the lint free cloth provided, very lightly wipe the dashboard in one direction to remove any debris from the surface. Do not rub the surface as this could further affect the texture of the dashboard surface. Be sure to regularly turn over the cloth as it becomes soiled. This cleaning process can be repeated if necessary. Rinse the cloth thoroughly before re-using. Allow the dashboard to dry.

The dashboard cleaner is formulated specifically to prepare the sticky dash surface prior to applying the coating. Do not use the cleaner on the dashboard again for at least two weeks after applying the Surface Coating as it may soften or begin to remove the fresh coating. Please refer to the maintenance section for more information.

Sticky Dash Fix - Surface Coating (Step 2)

The dash should feel dry or much less sticky after cleaning, but the stickiness will eventually return over time or when exposed to high heat. Therefore the cleaning process should be carried out shortly before applying the coating. Do not apply the Surface Coating in direct sunlight or in hot weather as the product may dry on contact and may peel as more is applied. Do not apply if the temperature is below 10 degrees Celsius. To avoid dust particles sticking to the coating when it is wet, don't apply the coating on a windy day or alternatively apply in dust-free enclosed area. Shake the bottle thoroughly before use. Check for a correct colour match by dabbing a little of the product, using a sponge or cloth, to a small inconspicuous area and allow to dry before inspecting.

Use masking tape to cover the sunlight sensor which is usually located at the bottom middle of the windscreen, or to the left or right side of the dashboard. Also mask the trim at the base of both windscreen pillars and any other areas such as the heater vents. If you do manage to get some coating on the windscreen glass, wait until your dashboard is completely dry then peel the coating off the glass or if still wet, apply some methylated spirits to a cloth and wipe the coating away, followed by a clean with regular window cleaner. The coating will not adhere to poly-propylene (plastic parts such as hard interior trim) and will simply peel off if desired, but it is always best to mask these areas rather than clean them. When removing masking tape, be careful not to pull up the Surface Coating.

Pour a small amount of the coating onto a small plastic tray, lid or a disposable plastic plate. To begin with, only apply the Surface Coating to one side of the foam brush, this will allow you to get into the areas where the windscreen meets the dashboard, without getting the Surface Coating on the glass. Apply a light coat, in one direction, to the areas closest to the windscreen. The section closest to the windscreen is usually the worst affected because it traps heat and becomes the hottest when exposed to sun-light, this area will require multiple coats. Make sure you routinely wipe the foam applicator brush with a dry cloth, to remove any debris which may have been missed when cleaning this area. Be sure to flatten any air tiny air bubbles on the surface, before the coating begins to dry. Wash the foam applicator sponge with water or wrap in cling wrap, between coats to preserve it.

Allow 30 minutes for the product to dry before applying another coat or a hair-dryer on a low setting may be used to speed-up the drying process. You will know when an area has been sufficiently coated, because it will no longer feel sticky to touch when dry. Apply the coating to other affected areas of the dashboard. It is possible to only coat the affected sections of the dash and lightly blend in the surrounding area.

Chips, gouges and scratches to the dashboard surface can be improved and filled by using a suitable flexible filler to fill indentations and then the colour-matched Surface Coating applied over it to conceal the repair.

! This Surface Coating is not suitable and should never be used in an attempt to fill or conceal cracks in your dashboard.

Although the product is touch-dry in minutes, the coating will continue to cure and strengthen over time. The coating can be stored (not in vehicles) and re-applied if ever required.

Use water to clean up.

WARNING! - AIRBAG CAUTION

Most modern cars are equipped with a passenger-side airbag that deploys through precisely designed perforations in the dashboard. The parts affecting airbag release are designed with great attention to detail, with the recognition that in an accident it is essential that they deploy as designed. Thus the spacing and size of the perforations designed to facilitate the properly timed and located airbag release are subject to extremely precise specifications.

It is vitally important that this area is not covered or restricted in any way. Please refer to your vehicle's owner manual or contact your vehicle's manufacturer to ascertain where the passenger airbag perforations are located and DO NOT APPLY THE COATING OVER THE AIRBAG PERFORATIONS OR AIRBAG DEPLOYMENT AREA. Never apply the coating to the driver's airbag cover or to any other areas from which airbags deploy. If applied in error, wet coating may be removed by gently wiping the area with a soft cloth dipped in methylated spirits. Coating which has completely dried will, begin to soften in contact with the methylated spirits and begin to wipe away.

USEFUL TIP: If the passenger-facing section of the dashboard is affected and requires coating, masking tape can be used to exclude the area from which the passenger airbag deploys and removed while the coating is still wet. To minimize noticeable lines, wait until the coating is dry and using a finger or applicator dipped in methylated spirits, gently soften and smooth the edge of the coating line. After the coating has properly cured, the Sticky Dash Fix - Dashboard Cleaner can be used occasionally to treat the un-coated section.

Maintenance

No special maintenance is required. Clean as normal with soapy water. Avoid commercial cleaning products. ! Never apply detailing products or dressings to the coated dashboard.

Trouble-shooting

Bad adhesion - residue from previously applied silicone dressing, is the most common cause of poor adhesion to areas or patches of the dashboard surface. If the Surface Coating is applied to a contaminated area, the coatings may disperse (spread out), appear patchy or peel off easily. Clean the affected area gently, using a finger or applicator dipped in methylated spirits (do not rub). On a positive note - if the coating does peel, it will often take most of the contaminant with it. Thoroughly clean or change the applicator, before re-applying the coating to the area, using a light dabbing or patting technique. Be sure to flatten any air bubbles before the coating begins to dry.

Shrinkage - if the coating is applied in direct sunlight or when the dashboard is hot, the coating may dry too quickly and shrink, resulting in a "crocodile skin-like" appearance. Use methylated spirits on your finger or applicator to soften and smooth the coating, allow the coating to dry.

Peeling - if the coating is not left to dry properly in-between coats, the membrane may peel when you apply the next wet coat. (Also see - Bad adhesion)

Broken or torn membrane - a break or hole in the Surface coating can be rectified by dipping a finger or applicator brush in methylated spirits and then lightly smoothing and flattening the edges of the broken coating and then re-applying the coating to the missing area using a light dabbing or patting technique. Be sure to flatten any small air bubbles. Once dry, the section can be lightly blended with the surrounding area.

Debris stuck in coating - methylated spirits can be used to soften the Surface Coating to remove debris or hairs which have attached to the coating during application and dried on the surface.

Section remains tacky - each dashboard has been exposed to different conditions over time and will vary in condition. Certain areas of the dashboard are exposed to more light and heat and will require more coats to seal the surface. If you have missed a spot during application or more coats are required to an area, simply repeat the application procedure without using the dashboard cleaner. The dashboard should feel dry even when parked in the hot sun. Never press down hard or poke the surface of the dashboard when it is hot, as the underlying surface (not the coating) may be soft.

Streaking - apply the Surface Coating evenly using a consistent amount of coating on the applicator. In addition to the foam applicator brush provided, a small foam sponge such as a cut-up kitchen sponge can also be used to better blend the area.

Thread

Thread Starter

Forum

Replies

Last Post

Florida Guy

General Tech

47

01-07-2024 10:48 PM